-

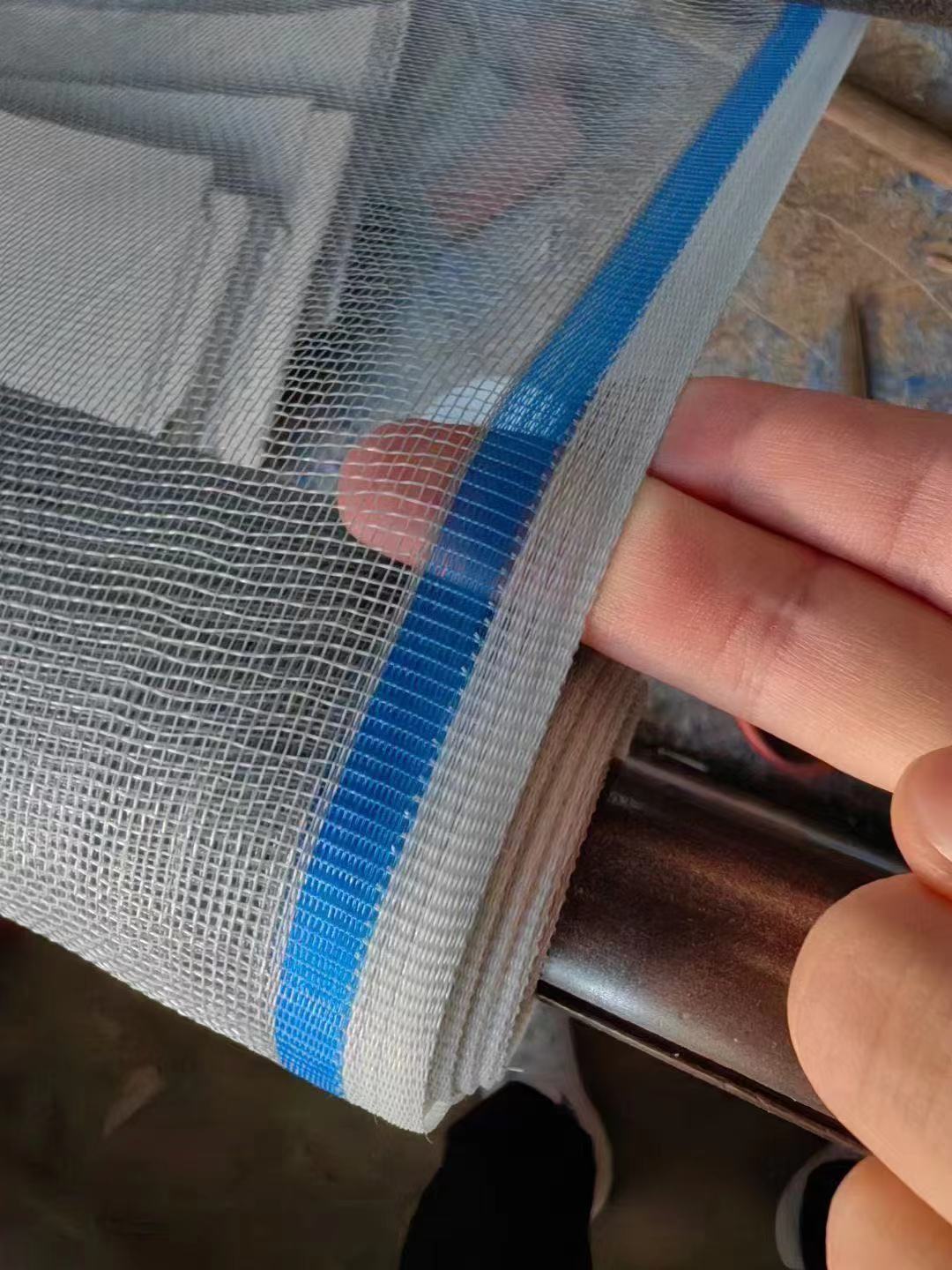

Plastic window screen

Plastic window screen is a product made of polyethylene, polyvinyl chloride, nylon and other plastic materials, also known as polyethylene window screen or nylon window screen. It is mainly used for insect prevention and ventilation of Windows and doors, and has the characteristics of lightweight, durable and easy to clean. In addition, the weaving methods of plastic window screens are mainly flat and oblique weaving, and the colors are white, gray, black and so on.

Advantages of plastic screen:

1. Strong durability: Plastic window screens are made of high-strength plastic fibers, with excellent weather resistance, wear resistance and UV resistance, and long service life.

2. Easy to clean: The surface of the plastic window screen is smooth, not easy to absorb dust, just wipe with a wet cloth to keep it clean.

3. Good ventilation: plastic window mesh is large, good ventilation, can effectively adjust the indoor temperature and humidity.

4. Good insect protection: plastic window screens can prevent mosquitoes from entering the room and effectively protect the home environment.

5. Easy to install: plastic window screens are easy to install, just fix the window screens on the window.

Plastic window screen application:

1. Home Windows and doors: Plastic window screens are widely used in home Windows and doors, which can effectively block mosquitoes and ventilation.

2. Office Windows and doors: Installing plastic window screens on office Windows and doors can effectively prevent mosquitoes and ventilation, while protecting documents and information in the office.

3. Industrial use: In the industrial field, plastic window screens can be used for ventilation and insect prevention in factories, warehouses and other places.

4. Agricultural use: In the agricultural field, plastic window screens can be used for ventilation and pest control in greenhouses, farms and other places.

In short, plastic window screens as a durable, easy to clean, good ventilation pest control products, in the home, office, industry and agriculture and other fields have been widely used.

Plastic screen maintenance and maintenance:

1. Regular cleaning: the surface of the plastic window screen is easy to accumulate dust, and it needs to be wiped regularly with a wet cloth to keep it clean. When wiping should avoid the use of strong acid and alkali detergent, so as not to cause damage to the window screen.

2. Avoid sharp objects scratching: Although plastic window screens have better durability, they should be avoided from being scratched by sharp objects, such as scissors, blades, etc. If there are scratches, they should be repaired or replaced in time.

3. Avoid high temperature: plastic window screens are easy to deform in high temperature environments, so long-term exposure to sunlight or high temperature environments should be avoided.

4. Regular inspection: Regularly check whether the mesh of the plastic window screen is smooth, and if there is a blockage, it should be cleaned up in time. At the same time, check whether the window screen is off-line, damaged and other phenomena, if so, it should be repaired or replaced in time.

5. Correct installation: When installing plastic window screens, ensure that the window screens are smooth, wrinkle-free and firmly fixed. At the same time, attention should be paid to the ventilation of the window screen to avoid too dense installation affecting the ventilation effect.

In short, proper maintenance and maintenance can effectively extend the service life of plastic window screens and maintain their good ventilation and insect resistance. At the same time, the choice of high-quality plastic window screens brand and model is also an important factor to ensure its performance and service life.

-

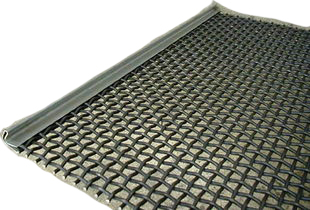

Mine Screen Mesh

Mine Screen Mesh

Mine screen mesh, also known as mining screen mesh, is a type of metal mesh used in the mining industry. It is made of high-quality stainless steel wire or other materials and is woven into a square or rectangular mesh structure. Mine screen mesh is used for filtering, separating, and sizing various materials in mining operations.

The main function of mine screen mesh is to separate different sizes of materials and ensure the uniformity and quality of the final product. It is commonly used in the mining of coal, iron ore, gold, copper, and other minerals. The size of the mesh openings can vary, depending on the specific requirements of the mining operation.

Mine screen mesh is highly durable and resistant to wear and tear. It can withstand harsh conditions such as high temperatures, heavy loads, and abrasive materials. This makes it suitable for use in various mining processes, including screening, dewatering, and classifying.

There are several types of mine screen mesh available, including woven wire mesh, perforated metal mesh, and polyurethane screen mesh. Woven wire mesh is the most common type and is known for its high strength and excellent filtration capabilities. Perforated metal mesh is often used for larger particle sizes and high-volume applications. Polyurethane screen mesh is known for its flexibility and resistance to abrasion.

In addition to its primary function of material separation, mine screen mesh also plays a crucial role in ensuring the safety of mining operations. By preventing oversized materials from entering downstream equipment, it helps to prevent equipment damage and maintain efficient operation. It also helps to reduce the risk of accidents and injuries caused by material blockages or equipment failures.

The installation and maintenance of mine screen mesh are relatively simple. It can be easily installed on vibrating screens, trommel screens, and other screening equipment using bolts or clamps. Regular cleaning and inspection are necessary to ensure optimal performance and prolong the lifespan of the mesh.

In recent years, with the advancement of technology, mine screen mesh has undergone significant improvements. New materials and manufacturing techniques have been developed to enhance its durability, efficiency, and overall performance. For example, self-cleaning screen mesh has been introduced, which reduces the need for manual cleaning and improves screening efficiency.

In conclusion, mine screen mesh is an essential component in the mining industry. It provides efficient and reliable material separation, ensuring the quality and uniformity of the final product. With its durability and resistance to harsh conditions, it contributes to the safety and efficiency of mining operations. As technology continues to advance, mine screen mesh will continue to evolve and improve, meeting the ever-changing needs of the mining industry.

packing

loading

-

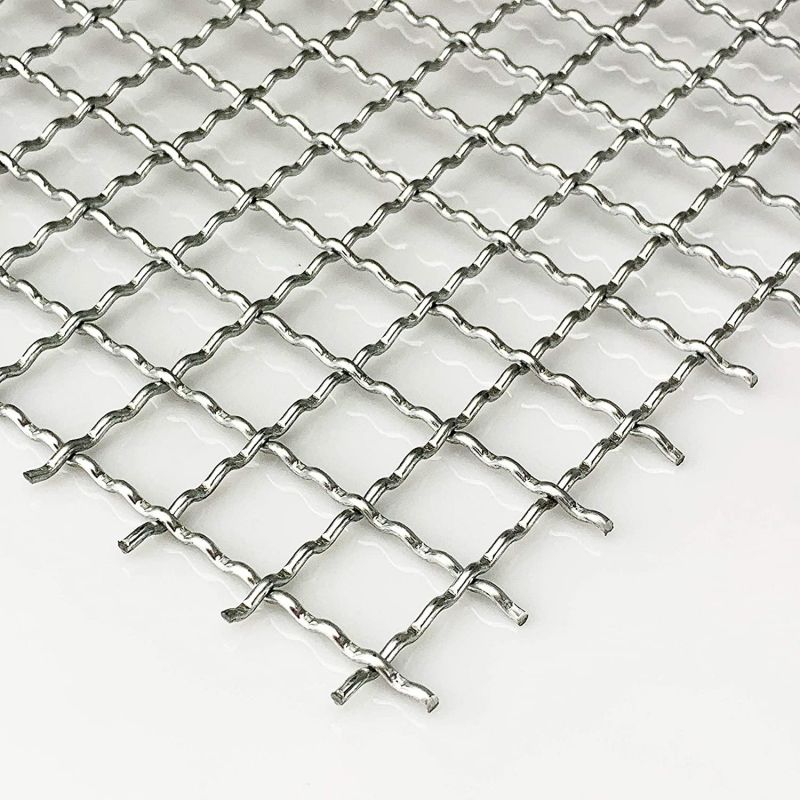

Crimped Wire Mesh

Wire Materials: stainless steel wire, high steel wire, low steel wire

Diameter:0.7-1.8mm

Weaving Patterns:Weaving after crimping Double/single crimped

-

Hot dipped galvanized chain link mesh

Features The strength of the wire is determined by its diameter. This is referred to as the ̶... -

High dipped galvanized grassland wire mesh

Grassland mesh is made of hot dipped galvanized wire, Outer and inner wire diameter is different, and outside wire with high t/s. This knot acts as a hinge that gives under pressure, then springs back into shape. This provides easy installation because the hinge “gives” while retaining full height for continuing protection and good looks. Vertical wires are individually cut and wrapped for maximum strength and flexibility.

-

Stainless steel wire mesh for gas-liquid separator

Material: SS304, SS304L, SS316, SS316L

Yutai is experienced in producing woven wire mesh and wire. Stainless steel wire mesh also named stainless steel wire cloth. Here we introduce stainless steel woven wire mesh and stainless steel woven wire cloth products.

Varieties according to materials:

304 Stainless steel wire mesh;

304L Stainless steel wire mesh;

316 Stainless steel wire mesh;

316L Stainless steel wire mesh -

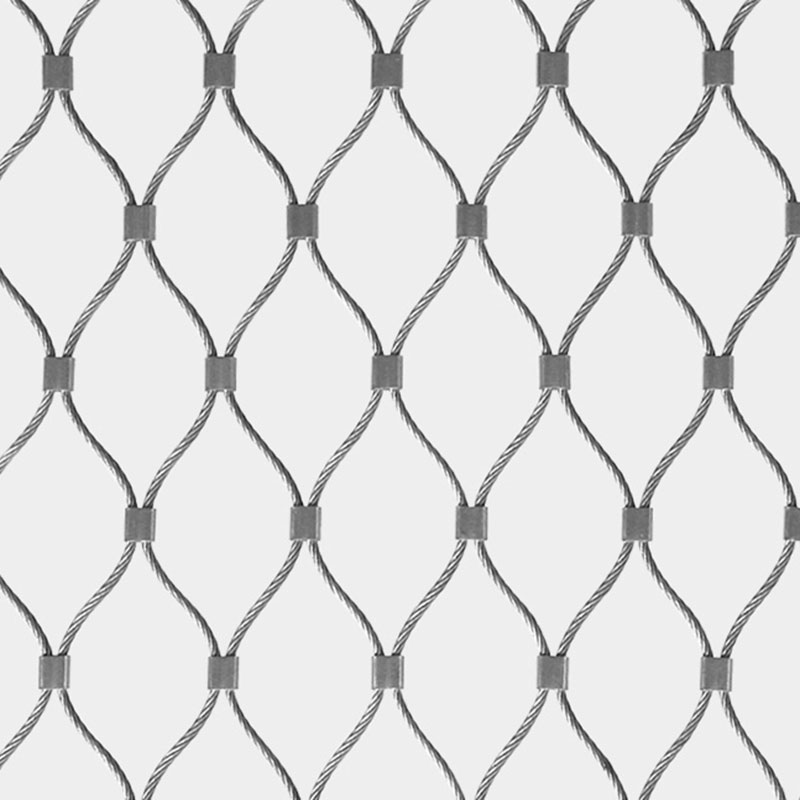

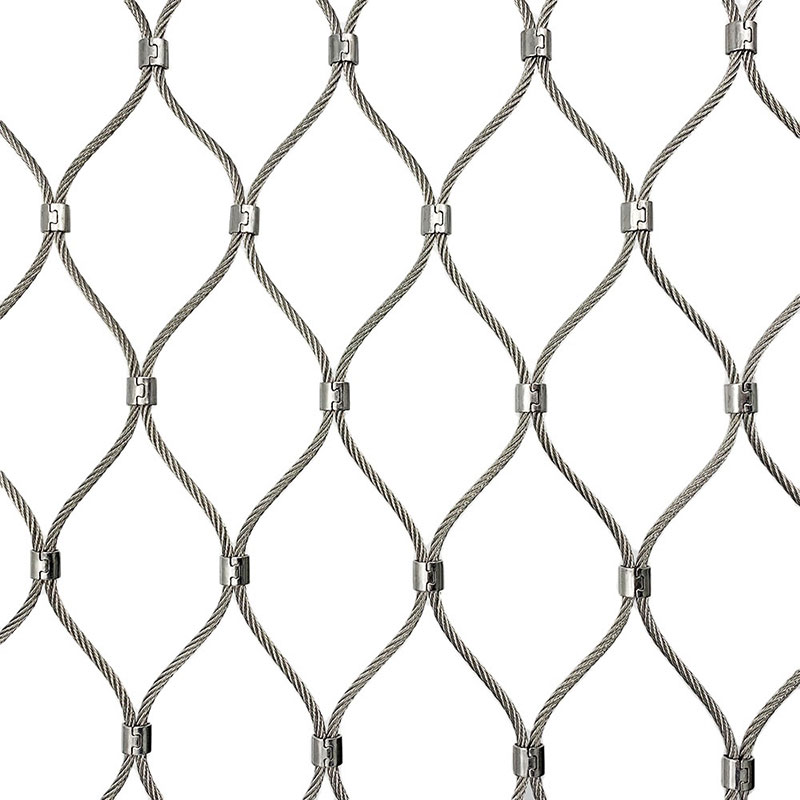

Stainless steel rope mesh for decorative and protection

wire rope structure: 7×7 rope, 7×19 rope.

Mesh specifications: 20×20mm, 30×30mm, 38×38mm, 51×51mm, 60×60mm, 76×76mm, 90×90mm, 102×102mm, 120×120mm, 150×150mm.

Diameter of wire rope: 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm.

Material: stainless steel 304, 304A 316, 316L.

Size: according to the size of customer’s construction scope and site, customized production after designing drawings.The size of stainless steel rope mesh needs to be selected according to the actual application environment. In order to facilitate customers to choose, Yutai stainless steel rope network factory will recommend common specifications for customers according to the installation experience, if the application environment is special, engineers can carry out on-site investigation, according to your requirements and specific application environment, put forward detailed material, rope diameter, hole distance and overall structure, and guide the installation.

-

Stainless steel rope mesh for zoo animal protection

Yutai modified products are suitable for different animal specifications, the material is 304, 304A, 316, 316L, silk rope structure is 7×7 rope, 7×19 rope and so on.

We will recommend wire rope diameter, mesh size and installation recommendations for each animal according to customer requirements.

Our Stainless Steel Animal Enclosure Mesh is an extremely strong containment netting suitable for smaller mammals, primates and large birds. Individual mesh knots are double fastened and the netting does not have to be installed under tension. The stainless steel zoo mesh is available in sizes from 25 x 25mm (1″ x 1″) to 125 x 125mm (5″ x 5″). In wire from 1.2mm to 3.2mm (3/64″ to 1/8″) in stainless steel. The hand woven netting is manufactured in 7 x 7 and 7×19 type 304 stainless steel to your requirements.

-

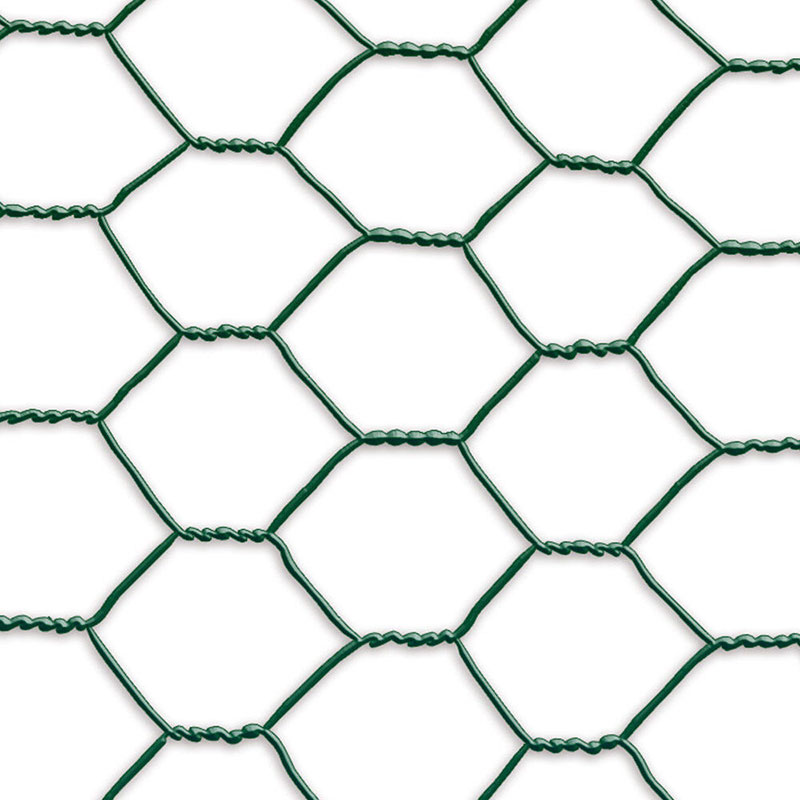

Hexagonal wire mesh

Hexagonal wire netting is also called Chicken wire, its materials with high quality low carton steel wire or stainless steel wire etc, as our leading goods, it could make electro galvanized, hot dipped galvanized and PVC coated

Hexagonal Wire mesh for chicken runs, poultry cages, plant protection and garden fencing. With a hexagonal mesh hole, the galvanized wire netting is one of the most economic fencing on the market.

Characteristics: the mesh is firm in structure and has flat surface. it has strong structure and smooth surface, and its weaving is artistic and practical.